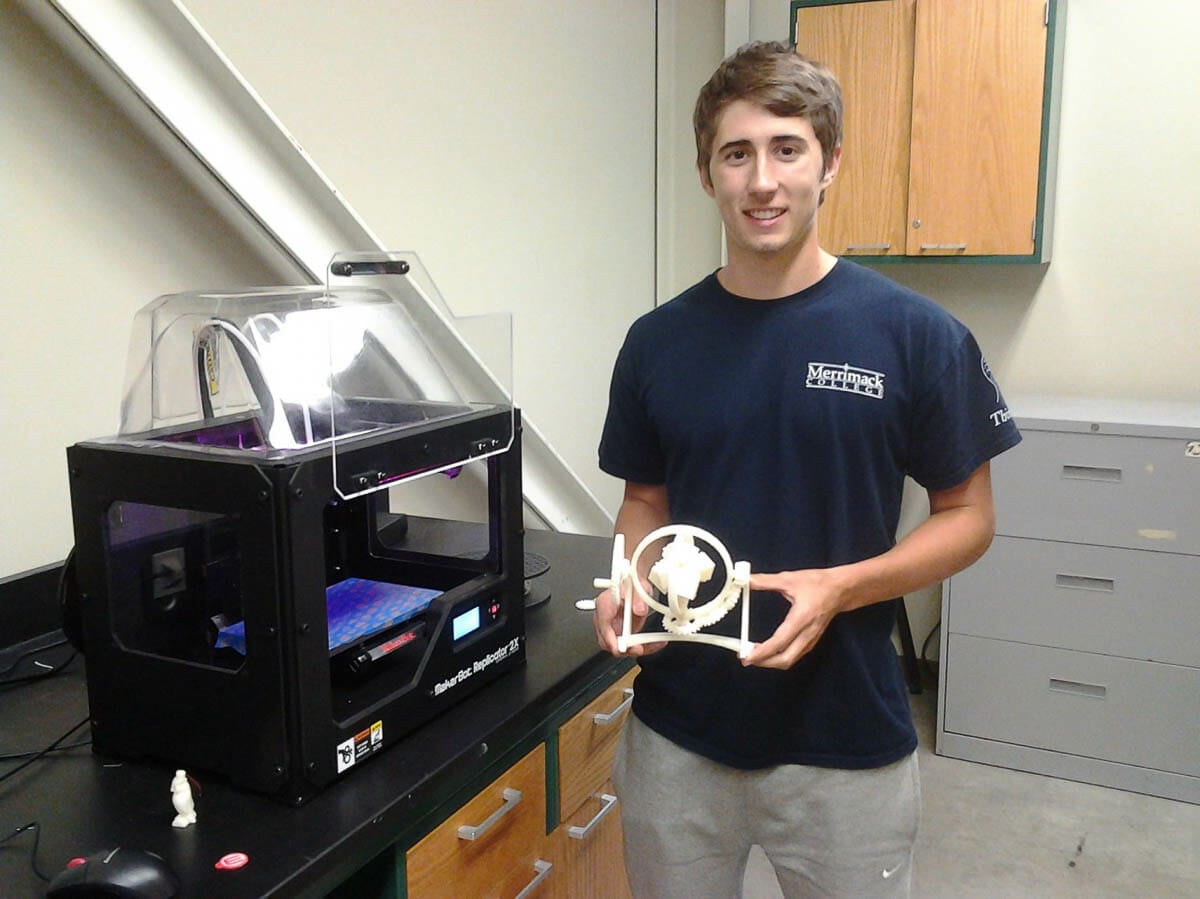

There were more than 30 plastic pieces in the gyroscopic cube that he made in Merrimack College’s Civil and Engineering Department during his free time over the summer, while working as a peer mentor to incoming engineering students.

The same three-dimensional scanner, printer and computer numerical control (CNC) that Stehnach used to make the gear system will be introduced into the department’s machine design course in second semester, said Associate Professor Franco M. Capaldi of the civil engineering department.

“When I made each piece for the gyroscopic gear it took a lot of time, and when all the pieces were done I had to file some of the pieces down so they fit properly,” Stehnach said. “When I finally put the last piece together I definitely felt a sense of accomplishment.”

The department is making greater use of the new 3-D printer and CNC system, which Stehnach used to make the gear system. Until now, students had only rudimentary methods of creating 3-D prototypes of their design work using store-bought parts, Capaldi said.

The department received its first 3-D printer near the end of the last academic school year and a second, larger printer over the summer. The printers are used for creating models and checking designs, in a process called rapid prototyping.

Calling the machines printers is a little misleading — they actually make 3-D objects either by cutting the shapes out of wood or metal blocks with a computerized router, or by spraying hot plastic in synchronized movements.

“I also enjoy watching the way the 3-D printer works, Stehnach said. “Seeing each component work in sync is like hearing an orchestra. Every component does its job to make the machine work.”

There are two places mechanical engineers can jump on board the rapid prototyping process.

The process can begin with the dimensions of an engineered product inputted to a computer that in turn feeds the information to the CNC, which can fit on a desktop.

Or, if there’s already a prototype to work from, the item can be put on a pedestal and its dimensions measured using lasers. Those dimensions are then transferred to the computer and to the CNC.

The CNC then makes a three-dimensional model of the design.

“Then you redesign and do it all over again,” Capaldi said.

Stehnach, 20, is a junior from Little Falls, N.Y. majoring in mechanical engineering.

He’s planning for a career working in alternative energy with an emphasis on wind energy.

By the end of the first week of the summer mentoring program, Stehnach got permission from Capaldi to work with the 3-D printer.

“I would come in here, start it, leave and come back an hour later, and hopefully it would be done,” Stehnach said.

Parts built on a 3-D printer can take anywhere from minutes to hours to make, Stehnach and Capaldi each said.

Through trial and error working on the printer, along with Capaldi’s help, Stehnach built his complex gear system using a design already installed on the computer.

He said he can see how it will be a useful tool during his college career.

“Since I’m interested in wind energy, I can design different blades and test them in our wind tunnel,” Stehnach said.

Manufacturers are already using 3-D printers in the production process.

A representative for iRobot who was a guest speaker during the mentoring program said the company always uses a 3-D printer before manufacturing begins, Stehnach said.